What’s Inside the eBook

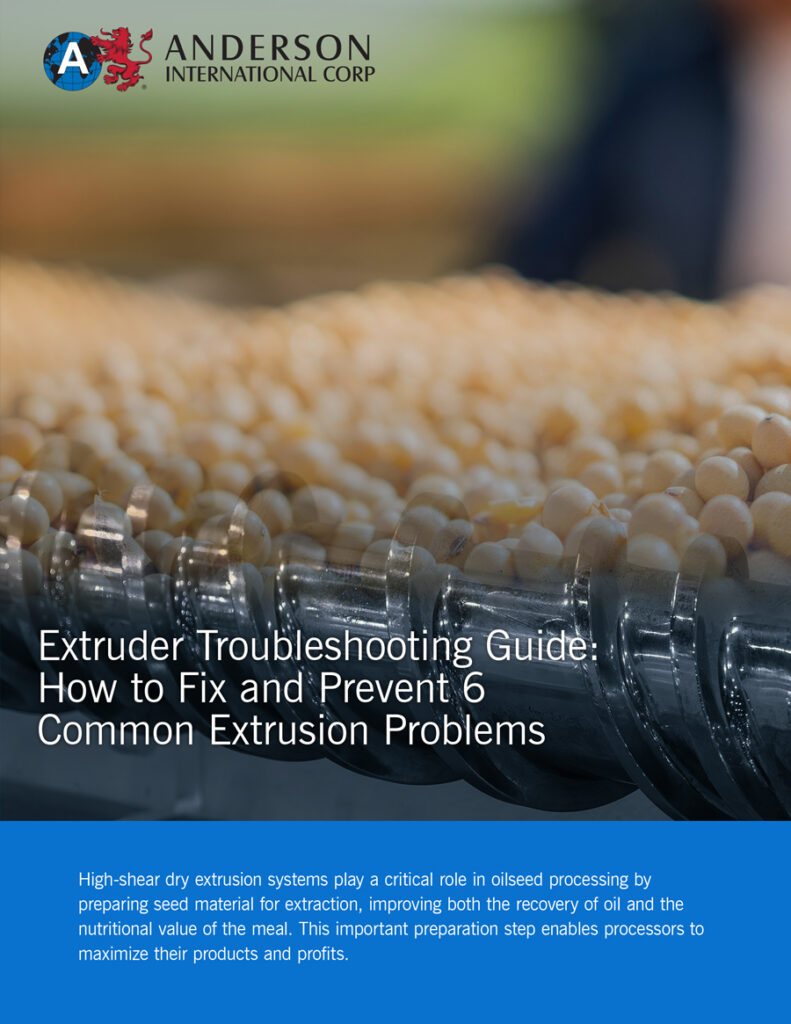

In this troubleshooting guide, we’ll explore the most common problems an oilseed extrusion operator might encounter, along with the most likely causes and tips to fix and prevent these setbacks.

Essentially, dry oilseed extruders like the Anderson Dox™ Extruder operate much like expeller presses, with a screw rotating inside of a barrel to push material through the machine. While the function of the expeller press is to extract oil from the seeds, the primary purpose of the extruder is to prepare the oilseeds for more efficient pressing.

Extruder parts are precisely engineered to generate pressure by compressing oilseeds inside the barrel. But over time, the internal components—such as barrel liners, breaker screws, worm flights, or choke inserts—wear down and erode, making it harder for the extruder to develop enough internal pressure and friction to break down oilseed material effectively.

These pre-processing steps significantly impact the performance of the extruder and the expeller downstream. To avoid problems stemming from variations in upstream seed treatment, consider implementing automated controls to monitor critical parameters like moisture and temperature.