Meet the Lion Series, Anderson’s Innovative New Line of Oil Presses Anderson’s newest line of presses, the Lion Series, represents the company’s culmination of over 135 years of pressing experience in the oilseed industry. The Lion Series comes in three sizes (600, 1200, and 1600) and is well-suited for pre-pressing and pressing extruded oilseeds. Key…

Managing Commissioning Expectations for a Successful Machine Startup

We have previously discussed startup commissioning, the methodical approach to installing, testing, and optimizing new pieces of equipment in a manufacturing line. This process ensures equipment operates as designed, preventing costly failures and downtime. It verifies quality, meets regulatory requirements, improves safety, and supports system integration. Commissioning leads to fewer errors, safer operations, and better…

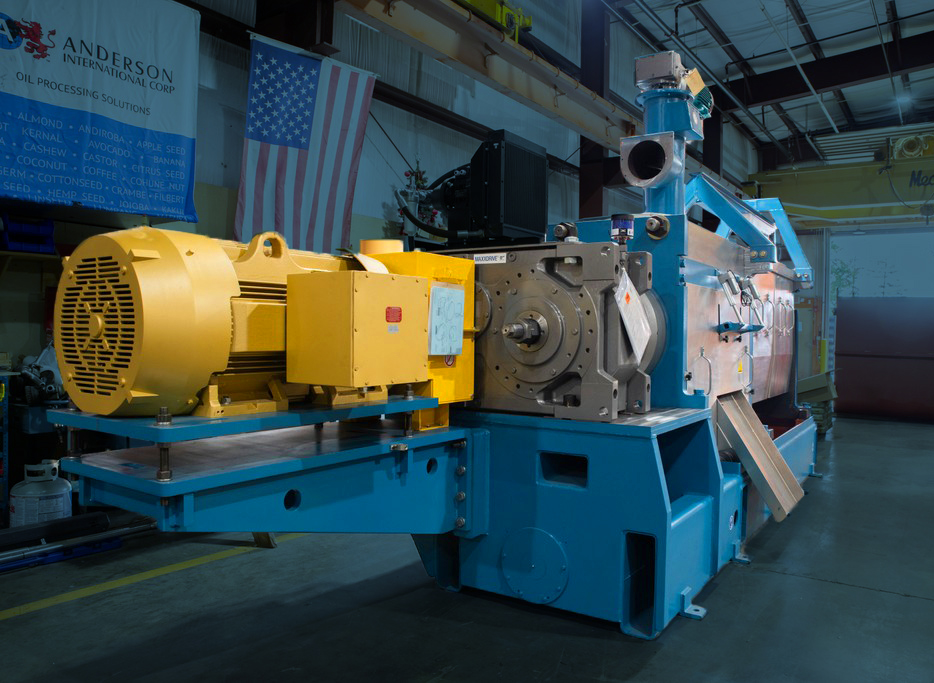

Introducing the Lion Series Expeller® Press Machines by Anderson

Since its inception in 1888, Anderson has been a pioneer in seed oil processing technology. For over a century, we have consistently demonstrated a commitment to invent and innovate, developing groundbreaking solutions that have shaped the industry. This rich legacy, spanning 135 years, is now further advanced with the introduction of the Lion Series Expeller®.…

Four Keys to Proper Soybean Storage

From the time soybeans leave the field until the moment they arrive at the processing plant for extraction, the storage conditions they endure can literally make or break your operation. Simply stashing seeds in a storage silo and forgetting about them until it’s time to start crushing can be a recipe for disaster. Proper soybean…

Avoiding Oil Mill Design Defects That Drain Profitability

Oil mills represent a major investment, and every design choice has lasting consequences. A single oil mill design defect can reduce efficiency, drive up maintenance costs, and limit future growth. From undersized conveyors to poor ventilation, the mistakes often seem small at first but become costly bottlenecks as production scales. By identifying common pitfalls, mill operators and…

Minimizing Oil Mill Operator Error in Your Soybean Processing Plant

Oil mill operators play a critical role in keeping a soybean processing plant running smoothly to produce high-value oil and meal. Unfortunately, everyone makes mistakes. In an industrial processing plant filled with expensive equipment and potential hazards, even the slightest oil mill operator error can have severe consequences. For example: Avoiding mistakes is crucial to…

Soybean Trading 101: Understanding the Basics of Trading Soybean Futures

Soybeans, the most popular oilseed on the planet in terms of production volume, have also become one of the world’s most widely traded commodities due to liquidity, versatility, and widespread value across many industries. If you’re looking beyond simply crushing these valuable beans, soybean trading can be a useful tool to manage the wild price…

More Energy, Less Processing: The Benefits of Full Fat Soy

Traditionally, the oilseed processing industry has focused on extracting oil from soybeans for human consumption, then feeding the remaining meal to livestock as a valuable source of protein. High-energy diets often require fat to be added back into the meal to meet the complete nutritional needs of certain animals. But another alternative is gaining popularity:…

Maximize your oil mill’s profits with an oil screening tank

Although the screw press tends to steal the spotlight as the ultimate workhorse in an oilseed processing plant, charged with the crucial task of separating liquid oil from solid meal, not even the highest-quality press will perfectly separate every particle. Pressed oil will inevitably contain a certain amount of solid residues known as foots. Recovering…