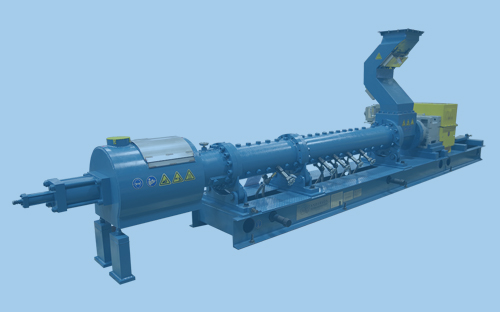

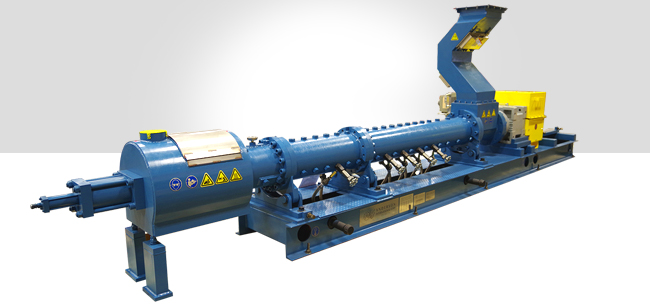

Designed to improve the efficiency of oil recovery in solvent extraction.

The Anderson Solvex packs material to be extracted into a dense, yet very porous structure. This value-add machine allows solvent easier access to the oil for extraction, resulting in up to 50% increases in extractor capacity, 40% reduction in solvent hold-up in the solid product (marc), 20% reduction of solvent in the liquid product (miscella), and an overall reduction in solvent losses.

50%

increase in extractor capacity

40%

reduction in solvent hold-up in product

20%

of solvent in the liquid product

Expanders, like the Solvex, lower overall plant energy consumption, and loading on the extractor, hence reducing their operational costs and increasing their capacity. The Solvex Expander can also reform dense pre-press cake into a porous collet for improved extractor efficiency on high oil content materials, providing similar benefits with soybeans.

How the Solvex Expander Works

The Solvex uses steam as its primary heat source. Using steam-generated heat, the screw propelling the material through the expander requires less horsepower per ton, allowing operators to process more material in a given timeframe.

Related Blogs

Benefits

Primary Benefits of Collets vs. Flakes:

- Up to 50% increase in extractor capacity

- Residual oil levels as low as 0.6%

- Reduction in fines

- Higher extractor percolation rates

- Lower solvent to meal ratios

- Higher miscella concentration

- Lower steam consumption

- Lower solvent loss

- Reduction in non-hydratable phospholipid content

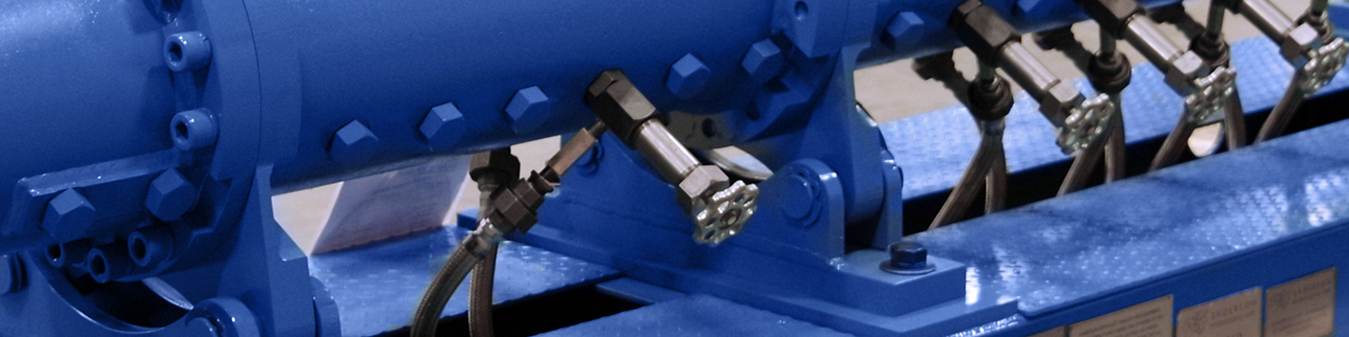

Highlights and Features

Highlights

- Can process more than 800,000 metric tons of oilseeds without maintenance downtime

- Can be quickly converted to our Hivex™ Expanders

- Can be fitted with either a multi-holed die-plate or a hydraulic cone choke

Features

- Die plate or adjustable cone choke discharge

- V-belt or gearbox drive

- Base for mounting and aligning all components

- Pin barrel mounting allowing for thermal expansion while maintaining

- Instrumentation package for remote operation through existing control system

- Pre-piped steam supply skid for local or remote control

- Hardened wear liners, worm segments, and shearing bolts

Applications

- Soybeans

- Cottonseeds

- Oilseed Pre-Presscake

Anderson Solvex™

| Model | Connected HP | Capacity (MTPD) | Steam (150 psi) |

|---|---|---|---|

| Solvex 800 | 125-200 | 200-400 | 500-1,000 lbs/hr (225-450 kg/hr) |

| Solvex 1000 | 150-250 | 500-800 | 1,250-2,000 lbs/hr (560-900 kg/hr) |

| Solvex 1200 | 300-500 | 1,200-1,800 | 3,000-4,500 lbs/hr (1,350-2,050 kg/hr) |

| Solvex 1400 | 500-750 | 2,000-3,000 | 5,000-7,500 lbs/hr (2,250-3,400 kg/hr) |