The COVID-19 pandemic continues to disrupt the global supply chain, with widespread shortages and shipping delays impacting nearly every industry. From basic consumer goods like food and electronics all the way to industrial equipment, product scarcity is pushing up prices and slowing down deliveries across sectors—including the steel supply chain that sustains Anderson International.

Manufacturers and customers alike are feeling the ripples of this unprecedented turmoil. To answer some of the most common questions about the impact on lead times and prices, here’s what you need to know.

Squeezing the steel supply chain

The supply chain bottlenecks started during the early stages of the pandemic in 2020. Factories around the world began to shut down, or at least lower their production capacity, because workers were either sick or in lockdown. Production dropped off sharply as a result, while steel mills and other businesses braced for an almost-certain recession.

Then, buying patterns changed instantly. Instead of going to work, dining out, or taking vacations, consumers redirected spending into their homes—driving up demand for DIY materials like lumber, as well as steel-heavy products like grills and appliances. The unpredictably quick rebound caught many steel mills off-guard as they scrambled to meet the uptick in demand.

This surge clogged the pipeline for transporting parts and raw materials to factories around the world. Meanwhile, the influx of incoming ships overwhelmed docks, causing a shortage of shipping containers as products piled up at ports. Top it off with a labor shortage of factory workers and truck drivers, and the shipping delays throughout the steel supply chain seemed to multiply—causing a cascade of manufacturing challenges.

Raising prices to meet steel demand

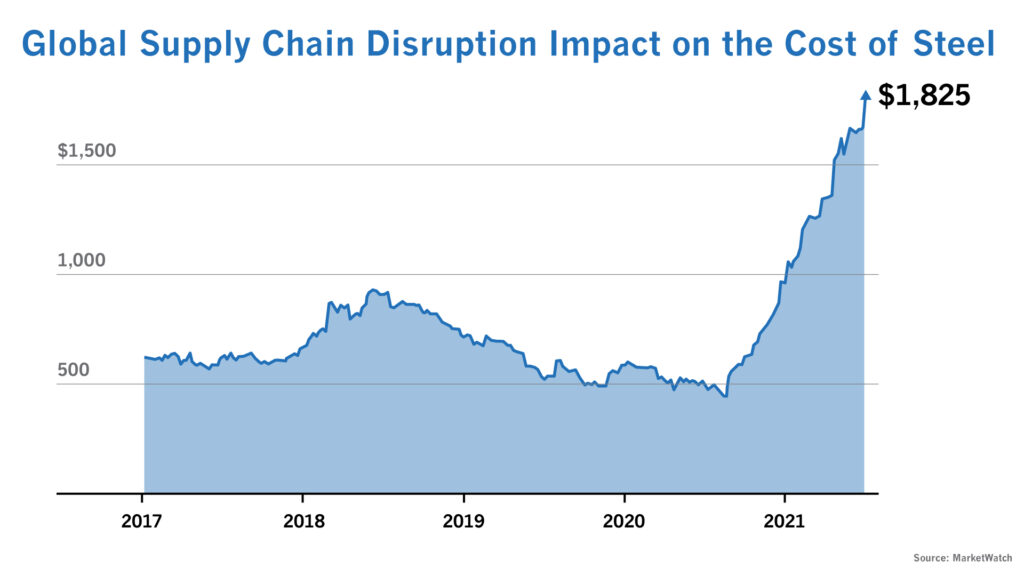

The combination of scarce supplies and higher demand led to skyrocketing costs through nearly every link of the steel supply chain. Since March 2020, steel prices soared over 300%. By the end of August 2021, the benchmark price for hot-rolled steel hit an all-time high of $1,945, compared to its “normal” range of $500 to $800 before the pandemic.

The U.S. government index that tracks the price of steel and iron nearly doubled from August 2020 to August 2021—marking the largest relative spike in metal prices since the index started in the 1920s. By October 2021, steel prices experienced 14 consecutive months of price increases, with short supplies during 10 of those 14 months, according to the Institute of Supply Management.

As a result, manufacturers like Anderson are facing the highest steel prices in years. Because we source raw materials to manufacture parts and equipment from various steel alloys, nearly all of our products have been impacted by these soaring costs. If we didn’t raise our prices to accommodate this shift, we would quickly put ourselves out of business.

That’s why our customers are seeing higher prices for our processing equipment—as well as many other commodities and consumer goods that have been impacted by the global steel supply chain disruptions. For example, the price of household appliances rose nearly 7% in August 2021—the highest year-over-year increase in a decade, according to the Labor Department.

Read more: Oilseed Production: Lower Capital Costs Do Not Always Equal Higher Profit

Anderson’s commitment to customers

Of course, higher prices aren’t the only ripple effect that our customers are seeing since the pandemic started. Steel supply chain issues are drastically affecting lead times, as well, so it’s taking longer for our team to receive the raw materials we need to produce parts and equipment for our customers.

While we’re working to boost our inventory of raw materials to counteract these challenges, we encourage our customers to similarly take stock of their equipment needs and place orders as soon as possible—knowing that it may take longer than usual to acquire spare parts and machinery.

Although the future of the global steel supply chain seems uncertain and, at times, even volatile, these economic shifts do not impact Anderson’s promise to our customers. As an industry leader for over 130 years, we continue to stand by our products and provide complete support throughout the lifetime of our systems.

Our company’s success is ultimately measured by the profitability that our customers derive from our technologies. So, even when our prices increase, Anderson remains committed to providing the service, expertise, and support that will ultimately make our customer’s operations successful.

For more information on ordering Anderson equipment, contact us today.